The Definitive Guide to Mhs - Material Handling Supply Inc.

The Definitive Guide to Mhs - Material Handling Supply Inc.

Blog Article

Mhs - Material Handling Supply Inc. - Truths

Table of Contents6 Simple Techniques For Mhs - Material Handling Supply Inc.Unknown Facts About Mhs - Material Handling Supply Inc.The Of Mhs - Material Handling Supply Inc.An Unbiased View of Mhs - Material Handling Supply Inc.Some Known Details About Mhs - Material Handling Supply Inc. Mhs - Material Handling Supply Inc. Fundamentals ExplainedExcitement About Mhs - Material Handling Supply Inc.

Generally, this devices is usually made use of in a business setting to relocate goods and products. There are 4 major kinds of product handling devices that assist storehouses and manufacturing facilities move and keep goods, which are: Transport Tools Positioning Equipment Device Lots Formation Equipment Storage Tools Industrial trucks, like forklifts, autumn under material handling tools and are utilized to relocate heavy materials securely.

As the name suggests, you can sit down when running a sit-down rider. Compared to standing using a stand-up rider. On top of that, sit-down cyclists are understood for moving at rapid rates. Especially when raising and lowering. Hence, running at a high quantity. Harsh terrain forklifts are built to operate at construction sites or other locations on unequal surfaces.

The 6-Minute Rule for Mhs - Material Handling Supply Inc.

When it pertains to product handling forklifts, telehandlers can reach the greatest altitudes and lug one of the most weight - Forklift dealer. With a slim aisle forklift, you can do even more with less area. Slim aisle forklift vehicles are made to be made use of in aisles that gauge much less than 10 feet by 12 feet

An is a kind of product handling devices used to pick and deliver goods from storage space for orders. Additionally, order pickers let drivers easily and promptly pick products from bins of various SKUs for order satisfaction. are the simplest type of forklift and are used to move pallets in storage facilities.

A likewise known as a, is a mechanized forklift utilized to assist construction employees in getting to high altitudes for tasks and projects. There are a number of different types of airborne lifts that are made for different construction jobs which we've detailed below.

The Best Strategy To Use For Mhs - Material Handling Supply Inc.

Utilizing them, industrial workers can get to raised heights or hard-to-reach locations conveniently. Considering that there are numerous kinds of boom lifts, it is very important to learn the various features and functions of each. Telescopic Boom Lifts extend in a straight line and require even more area to operate. Additionally, among all types of airborne systems, they offer the biggest horizontal reach.

The combination of high lifts, reach, and flexibility of these platforms makes them a secure remedy - forklift rental watkinsville, ga. These vertical pole raises attribute wheels, hence making it very easy to move and transport the light-weight maker.

Mhs - Material Handling Supply Inc. Fundamentals Explained

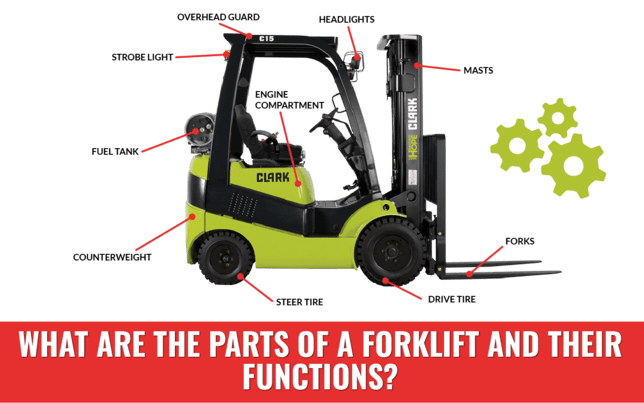

It is being thoroughly made use of throughout the market for moving materials and products. Forklift contains selection of components required to manage the task successfully. From Vehicle Frame, power source to weight are crucial for the forklift to work effectively. Vehicle Structure is one of the most essential element which forms the base of the device.

The Counterweight is a cast iron weight affixed to the rear part of the forklift. The goal of the counterweight is to counter equilibrium the lots that is being raised. On Electric Forklift, Counterweight is dealt with to the lead-acid battery. The forklift's source of power is composed of an interior burning engine.

Electric Forklifts acquire power from gas cells or Lead Acid Batteries. The carriage acts as the base to the forklift. The Carriage is fixed on mast rails to ensure that it can be quickly moved up and downward. The Mast is a vertical component that raises and lowers the tons.

Mhs - Material Handling Supply Inc. Fundamentals Explained

Air gets entrapped through the base of the cyndrical tube that enables gasses to go into without dripping them out. The quantity of gas in the cyndrical tube raises the stress inside it - https://pxhere.com/en/photographer/4245280. The pressure related to the location of the piston head produces a higher pressure. This pressure triggers the piston to go up, raising the quantity of the gas and reducing the pressure.

The Driver pushes the handle in an onward direction, signifying the forklift to this pump excess air to the cyndrical tubes. The operator pulls the deal with in backwards instructions that signals a special shutoff to release gas from cyndrical tubes. The hydraulic pistons are affixed to both main vertical frameworks known as "masts".

When the hydraulic pistons press the poles in higher direction, the equipments on the poles is pressed versus the roller chains. It happens because the one side of the chain is repaired to the immovable framework of the forklift, and the only method whereby masts can relocate up is when gears revolve in clockwise instructions and pull the forks overhead.

Fascination About Mhs - Material Handling Supply Inc.

There are 2 pairs of added hydraulic cylinders affixed to the base of the poles. When the Tilt Take care of is relocated in forward instructions, the air immediately loads up the chamber (Forklift dealer). The surge in pressure suffices to push the head of the piston and let the masts go away from the lorry's body

5 Easy Facts About Mhs - Material Handling Supply Inc. Shown

When the pistons are pressed onward, the poles are pressed back to the car. Forklifts have completely changed the storage and delivery markets. Forklifts were very first designed during very early part of the 20th century and now had actually come to be an important part of the contemporary industrial world. Forklifts are named after their fork-like prongs that lift up the load.

Report this page